- 40 Years of Experience

- Family Owned Business

- Stockist of Top Brands

- Knowledgeable Staff

Call Now!

Comprehensive Range of Shaft Couplings in the ACT

Shaft Couplings

CBS has a large range of couplings to suit various applications. Choose from everyday couplings like HRC and Jaw to Omega equivalent Max Dynamic couplings.

HRC Couplings

The HRC coupling is a proven performer, consisting of two cast iron flanges and a rubber element, which performs under compression. The modular design allows for a simple fitting and easy maintenance whilst the rubber element absorbs shock loading and compensates for marginal misalignment. CBS carries an excellent range of HRC couplings in Pilot Bore and Taperlock.

-

HRC Couplings

Button

-

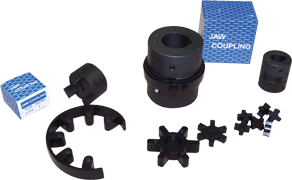

Jaw Couplings

Button

Jaw Couplings

The Jaw coupling is recognised across a large range of industries. The Jaw coupling is highly resilient, it does not require any lubrication and can work in environments contaminated with oil, dirt, sand, moisture and grease. The rubber insert is designed to absorb shock loading and does not allow for any metal on metal contact. The inserts are available as Spider Element as well as Wrap Element Kits. We stock a range of Jaw couplings in a variety of pre-bored and keyed sizes.

Universal Joint Couplings

Self-locking assemblies provide reliable, high strength keyless connections by converting locking screw clamp loads into radial contact pressures applied simultaneously to both the shaft and the bore of the mounted component. The resulting zero-backlash mechanical interference fit will accommodate a high torque, thrust, bending and/or radial loads, and unlike other mounting technologies will never wear or pound out, even for high cycle fluctuating or reversing loads.

When the locking unit’s bolts are tightened, plates engage with both the shaft and the inside circumference of the driven component. The locking assembly distributes the applied pressure evenly. No keyways or grubscrews are required with this device.

-

Universal Joint Couplings

Button

-

Jaw Couplings

Button

Jaw Couplings

We stock a range of Universal Joints in D Type and HD Type – blank bores only. The blank bore allows for any bore diameter up to the recommended maximum.

D-Type – Multi-purpose industrial type, standard pin and block design.

HD-Type – The Heavy Duty model benefits from its strict compliance to engineering detail. The HD type employs hardened yokes and pins to vastly improve the Universal Joints resistance to wear and shock loading. This attention to detail extends the life of the HD type Universal Joint by up to two times in comparison to that of the standard D type.

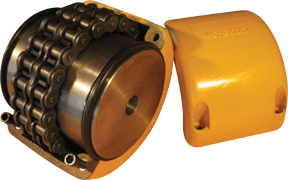

Chain Couplings

The chain coupling consists of two sprockets joined together by a standard duplex roller chain. This highly compact structure provides high flexibility between shafts, power transmission capabilities and is durable and robust. Chain couplings allow for easy maintenance and is a simple easy on/easy off process. Our chain couplings are supplied with casings standard.

-

Chain Couplings

Button

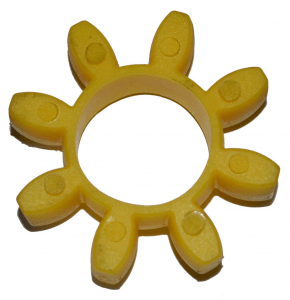

Curved (Rotex®) Jaw Couplings

The curved jaw design has a radial curvature to the jaw face and both radial and axial curvature (crowning) to the spider element. This provides better torsional softness and an angular misalignment capability.

The curved jaw type coupling gives reliable service for light, medium and heavy-duty electrical motor and internal combustion engine power transmission applications. Common applications for curved jaw type couplings include connecting power sources to pumps, gearboxes, compressors, blowers and fans, mixers, conveyors and generator sets.

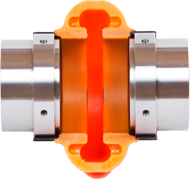

Flexible Tyre Couplings

CBS stocks a range of highly flexible tyre couplings. Consisting of two flanges, the two halves are joined by a rubber tyre. The tyre itself is soft and flexible; this allows the tyre coupling to compensate for large amounts of shock loading and backlash, as well as both parallel and axial misalignment.

Highly Flexible – It compensates for misalignment, up to 4° angular, 6mm parallel, 8mm axial. You can expect torsional flexibility of up to 12°, at maximum torque.

-

Flexible Tyre Couplings

Button

-

Cone Ring Couplings

Button

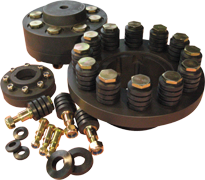

Cone Ring Couplings

Cone Ring Couplings are based on a time-proven design. The coupling consists of two flanges interlocked with a number of elements, depending on the coupling size.

The Cone Rings Couplings unique flexible element comprises of tapered rubber rings mounted on steel pins. The rubber rings absorb commonly encountered misalignment, shock and vibration.

The Cone Ring Coupling is as popular as ever for its ease of maintenance. No Lubrication is required. The pin and rubber design ensure trouble-free maintenance, as they can be removed and changed without the need to take the coupling off the shafts. The flanges are high-grade cast iron, the pins are hexagonal steel bar and the rings are synthetic rubber.

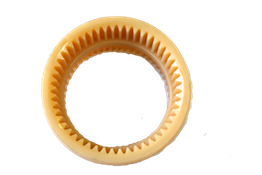

Curved Tooth Gear Couplings (HRC®)

The Curved Tooth Gear Coupling consists of 2 geared hubs and a curved tooth nylon sleeve.

Product Characteristics:

- Double-section type curved-tooth gear coupling

- Widely applicable in various mechanical and hydraulic fields

- Nylon and steel matched, maintenance-free

- Able to offset axial, radial and angular misalignments

- Axial plugging assembly, very convenient

-

COUPLING-RGF-Side

Button

Nylon Toothed Sleeve Characteristics:

- Excellent mechanical performance

- High rigidity

- High temperature resistance (+100C)

- Not brittle at low temperature – Good slippery and frictional behaviour

- Excellent electrical insulation behaviour

- Chemical corrosion endurable

- High accuracy of processing

-

COUPLING-RGF-Nylon-Sleeve

Button

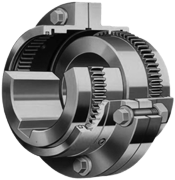

Gear Couplings

KCP gear couplings follow the international standards of AGMA and JIS, which easily allows you to replace major industrial products. Our gear couplings compensate angular misalignment, parallel misalignment and end float. The fully crowned hub teeth provide minimum loading stress and ensure longer life.

Characteristics

- High torque, small size, long life and very little loss of transmitting power

- The concave-convex flange design allows easy assembly and the high-quality gasket prevent leakage of lubricant.

- Gear Coupling permits parallel, angular misalignments and end floating by crown gear teeth

- The coupling made of S45C has good endurance to high speed and peak load

- Customer’s requirements of special design can be delivered

-

Couplings-Gear-KCP

Button

Application

- Heavy load, but compact design coupling

- Highs speed up to 5,000rpm (Depending on size, refer to the data)

- Low speed, but high starting torque

- End float application

- Spacer required, due to long distance between shaft ends

- Low load and lightweight application is not recommended

Max Dynamic Couplings (Omega® Equivalent)

Characteristics of Max Dynamic® coupling:

- Facility protection for twirl and twist, impact and abrasion

- Very simple replacement and maintenance without oil and grease

- Very simple replacement without the separation of motor or connector on the related line due to its simple structure

- Possible for the dissimilar connection and assembling with the same hub

- Polyurethane based for having good water and chemical resistance

- Highest flexible elasticity on the run

- Less noise

Applications

- Agitator

- Blower

- Compressor

- Conveyors

- Cranes and Hoists

- Elevators

- Fans

- Generators

- Pump

- Brewery and Distilling

- Food Industry

- Lumber Industry

- Pulp and Paper Mill

- Rubber Industry

- Textile Mills

- Aggregate Processing Cement

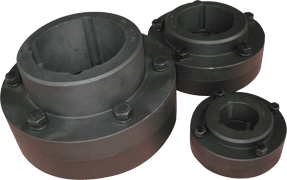

Rigid Couplings

Rigid couplings are used in situations where shaft alignment is essential. A misaligned coupling can cause damage and downtime. When properly fitted this torsional rigid coupling helps prevent any such events. Our rigid couplings are Taperlock ready and available in a range of sizes to accommodate almost any shaft size. Rigid couplings consist of 2 flanges, available in internal and external entry (H & F). This gives two possible coupling assemblies HF and FF. When connecting horizontal shafts, choose the most convenient method. When connecting vertical shafts use assembly FF only.

-

Rigid Couplings

Button

Taper Grid Couplings

You can enjoy the convenience and reduce costs by using KCP Taper Grid Steel Flexible Couplings. Key features include:

Parallel Misalignment

The movement of the grid in the lubricated grooves accommodates parallel misalignment and permits full functioning of the grid-groove action in damping out shock and vibration.

Angular Misalignment

Under angular misalignment, the grid-groove design permits a rocking and sliding action of the lubricated grid and hubs without any loss of power through the resilient grid.

End Float

Unrestrained end float of driving and driven members is permitted because the grid slides freely in the lubricated grooves.

Torsional Flexibility

Torsional flexibility is the advantage of KCP Taper Grid Couplings, providing flexible accommodation to changing load conditions.

Benefits

- When overload occurs, grid breaks and prevents breaking shaft or machinery parts connected

- When the parallel misalignment is too severe, the relating machine is protected by the virtue of shearing grid on tooth

- The life of parts (Mechanical Seal and Bearing, etc.) can be extended by more than double

- Quick installation and easy maintenance reduce labour cost and downtime costs

- KCP Grid coupling is interchangeable with major international brands

- It always transmits the power fully (100%) in low noise

You can use it for cheaper maintenance cost by changing damaged parts only

Application

Pin-Bush Flange coupling and Chain Couplings have usually been used, but now using the KCP Taper Grid Couplings, you will get many benefits:

- To reduce vibration and shock load

- For adequate power transmission under line misalignment

- For adequate power transmission under angular misalignment

- For adequate power transmission under end floating

- To prevent breaking of the machinery parts under overload

- When a reverse revolution is required

For smooth starting

Fluid Couplings

We stock soft start and mechanical fluid couplings with capacities up to 1200kW.

-

Fluid Couplings

Button

Not sure about the coupling you need? Give us a call on 02 6280 6884 for professional assistance.

VISIT US

45 Townsville St, Fyshwick, ACT 2609

OUR HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

MORE INFO

ABN: 56 065 010 531

Service Area: ACT, Snowy, Cooma, Goulburn, South Coast