Trusted Supplier of Timing Belt Drives in the ACT

Timing Belts and Pulleys

As a distributor of leading manufacturers, we have access to a large range of timing belts and pulleys. We can cater to the most powerful of industrial belts through to the lightest of drives, as well as replacement belts for supercharged cars.

Our main brands include Optibelt (Germany), Gates/Powergrip (USA), PTS Strongbelt (Germany) and PIX (India). If a specific brand is required that is not listed here, we can source it at the right price for you. We have timing belt catalogues for download and also a technical manual in our engineering section.

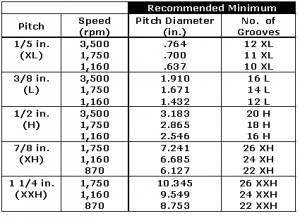

Timing Belts are one of the most important parts of power transmission drives. They exhibit important properties such as fixed speed ratio, no re-tensioning after installation, low maintenance with a wide variety of power transmission capacities and drive speeds. There are two main types of timing belt pulleys to suit the classical timing belt and the metric HTD timing belt. Classical timing belt pulleys are imperial in their measurements, have a square profile and use the designations XL, L, H, XH and XXH, while the metric HTD pulleys have rounded profiled teeth and their designations are 3M, 5M, 8M and 14M.

Timing Belt Pulley

This image shows a classical timing drive pulley and belt, showing proper fitment and worn fitment. During inspection, check for worn tooth sections on the pulley. The correct fit for the pulley contact is shown. A small amount of clearance should exist between the root section of the pulley teeth to prevent the belt from bottoming out.

Generally, positive drive belt pulleys are flanged to help keep the belt in position. On long centre drives, the belt may have a tendency to run to one side of the pulley. Stock or standard positive drive belts will ride toward the left flange, as indicated in the image. If only one flange is located on the pulley, it should be placed on the left.

Selecting Timing Belts

Classical positive drive belt sizes are:

- Pitch length

- Tooth pitch

- Belt width

The actual length of the belt is multiplied by ten to avoid the use of decimals in belt codes. For example, a 22.5-inch long belt is a code 225. The width of the belt is multiplied by 100; a 3/4-inch is referred to as a code 075. The image provides examples of positive drive belt codes.

Metric HTD positive drive belt designation:

Example: 800 8M 30

800 = Pitch length 800mm

8M = Section (Tooth pitch 9.0mm)

30 = Belt width 30mm