Widest Range of Quality V-Belts & Pulley’s in the ACT

V-Belts

Through the manufacturers we distribute to, we have access to one of the best ranges of V-Belts and pulleys available in the area. We can cater for the most powerful of industrial belts through to the lightest of V-Belt drives. In our resources section, you will find information on an online calculation tool, technical manuals on fitting and maintenance of V-Belts, ribbed belts and timing belts.

Our main brands include Optibelt (Germany), Gates (USA), Powergrip (Taiwan) and PIX (India). If a specific brand is required that is not listed here, we can source it at the right price for you. A range of catalogues are also available for download.

V-Belts come in a wide range of sections, lengths and styles. The sections (measurement across the top of the belt, widest part) and styles are below, we recommend you call us regarding the length required.

Standard V-Belts

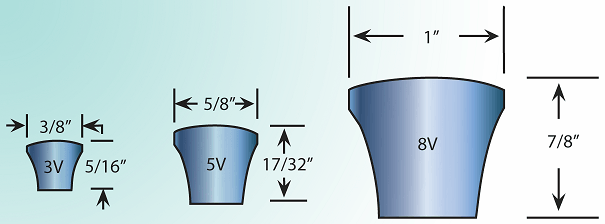

The A, B, C, D, and E belts, the narrow 3V, 5V, and 8V belts, and the light series 2L, 3L, 4L, and 5L belts are used in many applications. First, identify which type of belt should be installed on the machine’s pulleys. If there is any uncertainty, measure the top width of the old belt or use a manufacturer’s pulley and belt gauge.

The nominal dimensions of conventional, narrow, or light V-Belts may appear confusing. For example, the top widths of B and 5V belts are very close (1/32nd of an inch). The 5V belt is considerably thicker and the groove angles of the pulley are quite different. Using the one cross-section type on a drive designed for the other leads to short term belt life. Light V-Belts should never be used for heavy-duty industrial applications, even if they seem to fit the conventional or narrow V-belt pulley grooves.

Cogged V-Belts

Cogged V-Belts provide a higher horsepower rating than conventional cross-section belts. They are suited for drives with smaller pulley diameters where conventional cross-section V-belts would not be practical. Cogged V-belts, as shown, can be used on some heavy-duty A, B, C, and D drives as well as 3v, 5v and 8v drives. The designation added to the standard V-belt part numbering system for a cogged belt is by adding an x, i.e. ax, bx, 3vx, 5vx. The moulded notch in the belt’s bottom surface helps to reduce bending stress and provides uniform distribution of load. Notches also help to dissipate the heat of rapid flexing.

Power Band V-Belts

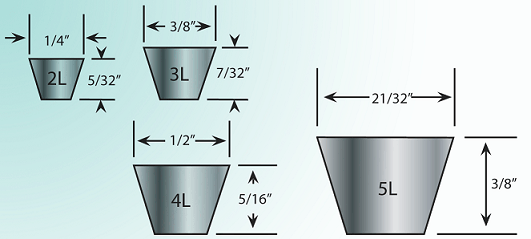

On some V-belt drives, fluctuating loads induce vibration, causing the belts to whip, particularly on the slack side. This severe belt whipping can result in the V-Belts rolling over in the groove or jumping off the pulley. In either case, the belts are quickly damaged. It is often impossible to eliminate the cause of the vibration. Therefore, to solve the problem of rolling or jumping belts, power band V-Belts are recommended for the drive.

The power band V-belt is made by adding a common back to the top of two or more belts. The belts and backing are vulcanized together to form a complete unit. The overcord section is thicker than on a normal V-belt, thus the backing rides well above the pulley. The same wedging action in the pulley groove is obtained as with a set of individual V-Belts. The backing provides for increased transverse rigidity. These figures show a cross-section view of a power band narrow and conventional V-Belts. These belts do not prevent vibration, they merely restrict it to an up and down motion, and prevent the belts from rolling over in the groove or jumping off the pulley.

Linked V-Belts

Linked V-Belts are used where it is very difficult to use endless V-Belts because of equipment design or as an emergency V-Belt to keep in your storeroom. The flexible links consist of laminated fabric and rubber and each is held together by twisting and going through the hole of the next. The belt can be installed or removed easily without removing outboard bearings, tilting, resetting, or moving motors or drive shafts.

V-Belt Pulleys

We have an extensive range of pulleys available to suit all cross-sections of V-Belts. Our standard pulleys are made of quality cast iron but we can get them manufactured in steel if required. Both are available with a pilot bore, bored and keyed or with a taperlock bush arrangement. We also offer light-duty aluminium and light-duty cast iron Biloc® pulleys. We can also manufacture special pulleys for the sawmill and agricultural industry. We have a fitting and maintenance guide available for download in our engineering section as well as catalogues for our common range of pulleys.

Pulley Alignment

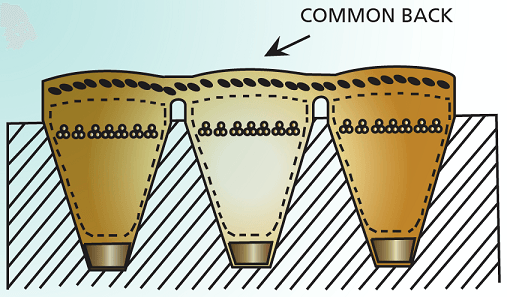

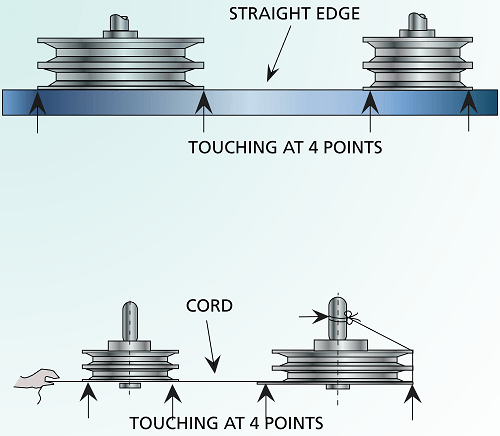

Proper alignment is essential to maintain long V-belt and pulley life. The best way by far to align your pulleys and to get it absolutely spot on is by using a laser aligner, but not everybody has that luxury, the drawings to the right show a couple of different ways to align your pulleys.

- By using a straight edge and touching the driver and driven pulleys at four points indicates good alignment. Use a square positioned from the base up to the pulley face to check if the pulley is perpendicular to the base.

- Shows how a tight cord can be used to check for pulley alignment. Tie the cord to the driven pulley shaft and bring it around the pulley face, bringing the cord to the driver pulley face, a quick check can be performed to see if the tight cord contacts the driver and driven pulley at four points.