Specialist in All Types of Conveyor Belting in the ACT

Conveyor Belting

CBS has been supplying the ACT area with conveyor belts for over 20 years. We have the ability to supply the lightest of belts through to the heaviest belt. The types of belts we can supply are as follows.

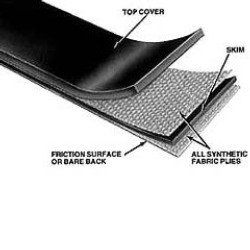

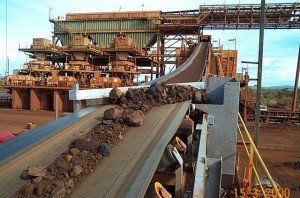

Rubber Conveyor Belt

Available in six single-stage and fourteen two-stage and three-stage sizes, the helical gear motors by SEW-Eurodrive ensure an optimal ratio between power and space requirements.

Our products have been tested & proven to provide the highest level of product performance in conveying technology. Our independence provides us with the ability to procure specific belts from recognized manufacturers that meet the needs of our customers ensuring the highest level of quality control at the best value for money.

We can supply belting in cut-to-width specific lengths, full rolls, vulcanized spliced endless belts, belts joined with mechanical belt fasteners or belts with ends prepared for own installation. We only market rubber conveyor belting produced by belting manufacturers who meet or exceed the applicable Australian Standards.

Our standard quarry rubber belt ranges from 450mm to 1800mm in the following designations:

- 2Ply PN150 N 3/1.5

- 3Ply PN150 N 3/1.5

- 3Ply Pn150 N 5/1.5

- 4Ply Pn150 N 6/2

- 4Ply Pn150 M 6/2

- 4Ply Pn200 M 8/3

Our Range includes but is not limited to:

- N Grade Rubber Conveyor Belt

- M Grade Rubber Conveyor Belt

- Crows Foot Weave (CFW) M Grade Rubber Conveyor Belt

- Quarry Master Rubber Conveyor Belt

- MOR Oil Resistant Nitrile Rubber Conveyor Belt

- HOR Heat and Oil Resistant Nitrile Rubber Conveyor Belt

- Heat Resistant Rubber Conveyor Belt

- E Grade Anti-Static Grain Handling Rubber Conveyor Belt

- FRAS Rubber Conveyor Belt

- Steel Cord Rubber Conveyor Belt

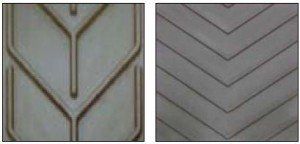

- Chevron Cleated Rubber Conveyor Belt

- Elevator Rubber Belt

- Rough Top Rubber Conveyor Belt

- Wedgegrip Rubber Conveyor Belt

- Custom Manufactured Rubber Conveyor Belt

- Other Rubber Conveyor Belts

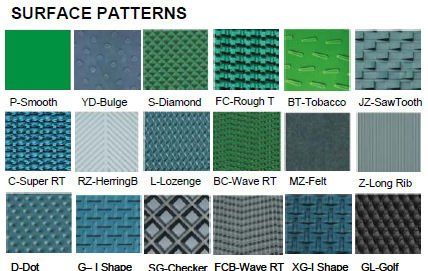

PVC and PU Conveyor Belting

CBS has a comprehensive range of PVC, PU and Thermoplastic Conveyor Belting. All our belts are manufactured to the highest standard to provide quality, variety of choice and economy in use.

By providing us with your specifications we can, in a timely and professional manner customise any of our belts to suit your application. We can also supply a complete range of Mechanical Belt Fasteners, PVC and PU Cleating, Sidewalls and Tracking Guides.

Our range of belts are available in four unique constructions:

- Solid Woven PVC Conveyor Belt

- Multiply PVC Conveyor Belt

- Sampla PVC, U and PU Conveyor Belt

- Thermoplastic Conveyor Belt

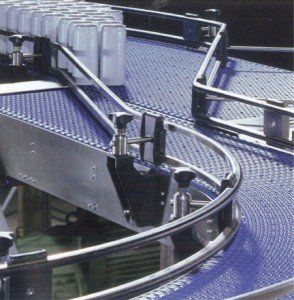

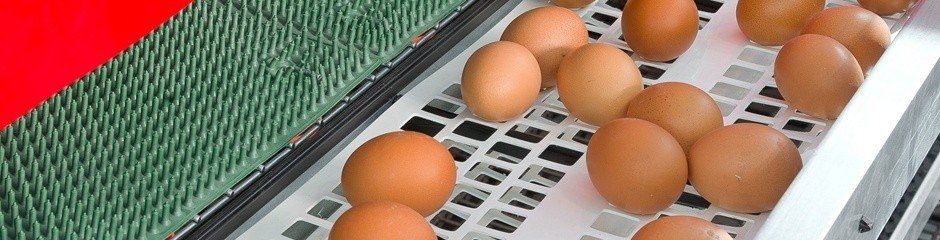

Plastic Modular Conveyor Belting

Plastic Modular Conveyor Belts from CBS offer versatility and durability compared to any other conveyor system. Our range of belt types are designed to convey a multitude of products – bakery goods, seafood, poultry, meat, packages, glass, timber, tyres etc. Belts can also be used for extreme applications, such as heat from ovens, cold from freezers, high-pressure wash downs and automotive component lines.

Our range of Plastic Modular Belts provide the following features/benefits:

- Positive drive and tracking eliminates the need for tensioning devices and significantly reduces belt edge damage.

- A comprehensive range of smooth rounded, open area designed belts providing, uniform and quick cooling, high water and air permeability and easy release of sticky products.

- Strong design for both straight and radius belts enable long runs without transfers.

- Solid design provides superior lateral rigidity.

- A broad range of belt materials provides for a multiplicity of conveying applications.

Power Transmission Belting

We can supply a range of high-performance Power Transmission Belting in rolls or cut lengths, with ends prepared for on-site splicing or custom-designed spliced endless. Specific tools for cutting, preparation of ends and for splicing these belts are available.

Their main application is in the following industries:

- Cardboard Industry

- Graphic Industry

- Wood-Based Panel Industry

- Paper Industry

- Printing Industry

- Textile Industry

- Flour Mills

- Marble and Tile Industry

- Packaging

- Material Handling

A number of our Power Transmission Belts can also be used as Light Duty Conveyor Belts. The Power Transmission Belt brands that we supply include Habasit and Siegling.

PU Round and V-Belt Sections

We supply a range of extruded Thermoweldable Round and V-Belt profiles which are used in various markets for transmission of light to medium duty, low speed drives and for conveying light loads. V-Belt sections are available with a range of top cover finishes and reinforcements suitable for both power transmission and light load conveying applications. Belts can be supplied in roll or cut lengths or as endless belts. Specific tools for cutting and splicing these belts are available.

Special Purpose Belting

CBS has access to a vast range of special-purpose belting, whether it be a conveyor or V-Belt. We can get nearly any belt manufactured to your specifications.

Our range includes but is not limited to:

- Air Permeable Belting

- Aluminium Extruder Belts and Roller Tubes

- Biscuit Webbing – Cotton and Polyester

- Blast Cleaning Tumbling Belts

- Bowling Alley Belts

- Carboxulated Nitrile Rubber Rough Top Conveyor Belt

- Checkout Belts

- Chicken Manure Conveyor Belts and Manure Curtains

- Cotton Laundry Belts

- Curve Conveyor Belts

- Deboning Belts

- Depanner Belts

- Dough Handling Conveyor Belting

- Draper and Combine Harvester Belts

- Egg Handling Production Belts

- Feeder Belts for Bulk Material Handling

- Feeder Belts for Panel Board

- Sanding

- Felt Belts – Truly Endless

- Filtration Belts

- Folder Gluer and Carrier Belts – Specialty Belt Range

- Grape Harvester Replacement Belts

- Haul Off Cable Pulling Belts – Specialty Belt Range

- Hay Baler Belts

- Harvester Belts

- Hot Stock and Water Belting

- Laundry Conveyor Belts

- Magnetic Separator Belts

- Marble Polishing Belts

- Meatcleat White FDA Nitrile Conveyor Belting

- Rubber Sidewall Conveyor Belt

- Sealed Edge Belting

- Slinger Belts – Truly Endless

- Table Top Conveying Chains

- Teflon® and Silicon/Glass Belts

- Tub Grinder Conveyor Belts

- Tufted Polyester Conveyor Belts

- Vertical Form-Fill-Seal Truly Endless Specialty Belts

- Waste Recycling Conveyor Belt

- Weigh Feeder Conveyor Belts

- Wide Width Conveyor Belts

- Wire and Metal Conveyor Belts

- Perforated Conveyor Belts

- Printing Blankets

- PVC and PU Thermoplastic Sidewall Conveyor Belts

Conveyor Idler Rollers

CBS has been supplying conveyor idler items for over 20 years, helping keep the conveyors turning in NSW. We supply items from DRC, Tyton and Prok which provides our customers quality products that meet all Australian standards at extremely competitive pricing. Our idlers, rollers and frames are widely used in collieries, quarries, timber mills, gold mines, iron ore plants and bulk material handling facilities. Besides the large rollers being used in the heavy industries, we also supply a range of smaller rollers for the packaging, food handling and smaller industries.

Our idler roller range includes:

- Trough Roller Sets

- Return Roller Sets

- Belt Training Guides

- Impact Idlers

- Troughing Idlers

- Flat Return Idlers

- Non-Standard Rolls are available on request

- Self-Aligning Troughing Idlers

- Self-Aligning Return Idlers

- Flat Carrying Idlers

- Vee Return Idlers

- Training Idlers

- Picking Idlers

- Garland Idlers

- Conveyor Head and Tail Drums

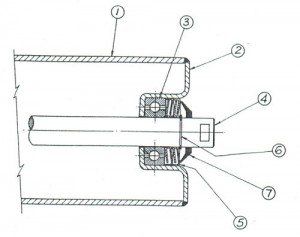

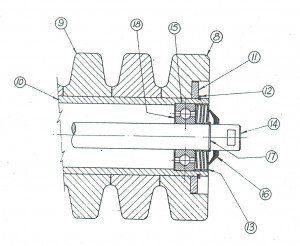

Breakdown Of Steel and Impact Conveyor Rollers

Typical arrangement of 76, 102, 114 and 127 diameter steel-faced conveyor rollers:

- Shell – 3.6mm wall tube to AS1450

- End Housing – 2.8mm mild steel

- Single row deep groove ball bearing No.6204

- 20mm Dia. precision bright mild steel shaft

- Multi labyrinth seal

- Standard shaft circlip

- Nitrile – PVC weather shield

- Outer rubber discs

- Inner rubber discs

- Steel tube – 60.3mm OD x 5.4mm wall

- Rubber discs retaining washer

- Circlip

- Multi labyrinth seals

- 20mm Dia. precision bright mild steel shaft

- Single row deep groove ball bearing No.6304

- Nitrile – PVC weather shield

- Standard shaft circlip.

- Fibre seal

We supply a range of steel, stainless steel and plastic rollers suitable for:

Conveyor Maintenance Products

CBS supply a large range of conveyor maintenance products and spare parts, ranging from belt fasteners for the mine, quarry and timber industries through to FDA approved plastic fasteners, pulley lagging material to stop belts slipping, adhesives, maintenance tools, belt cleaners and ploughs, load point products and belt trackers.

Conveyor Belt Fasteners

Choosing the proper mechanical belt fastener system is one of the most important steps in splicing a belt. Combining surprising strength and durability with affordability and easy installation, mechanical belt fasteners are a smart repair option — especially if your priority is a quality splice completed in short order.

Heavy-Duty Fasteners

| NAME | MIN PULLEY DIAM | KN/M MAX | BELT THICKNESS | PRODUCT FEATURES |

|---|---|---|---|---|

| Flexco® SR™ Rivet Hinged System | 127 mm-1050 mm | 60-350 | 3 mm-25.5 mm | 1. Low-profile, belt cleaner com1. Low-profile, belt cleaner compatible 2. Quick installation, minimal downtime 3. Power installation options 4. Maximum resistance to pull-outpatible |

| Flexco® BR™ Rivet Solid Plate System | 350 mm-900 mm | 70-140 | 6 mm-24 mm | 1. Low-profile, belt cleaner c1. Low-profile, belt cleaner compatible 2. Quick installation, minimal downtime 3. Power installation options 4. Maximum resistance to pull-outompatible |

| Flexco® Bolt Solid Plate System | 300 mm-1220 mm | 30-123 | 5 mm-32 mm | 1. Sift-free splice1. Sift-free splice 2. Non-magnetic and rubber covered options 3. On-site installation with portable hand and power tools 4. Low cost, long life splice |

| Flexco® Bolt Hinged System | 152 mm-230 mm | 33-52 | 6 mm-16 mm | 1. For belts with frequent 1. For belts with frequent belt-length alterations or smaller pulleys 2. Easy to install and re-install 3. Non-magnetic and spark-free optionsbelt-length alterations or smaller pulleys |

Light-Duty Fasteners

| NAME | MIN PULLEY DIAM | KN/M MAX | BELT THICKNESS | PRODUCT FEATURES |

|---|---|---|---|---|

| Alligator® Staple System | 50 mm-102 mm | 17-35 | 1.5 mm-6.4 mm | 1. Strong splice 2. Abrasion resistant 3. Simple installation method and tooling |

| Clipper® Wire Hook System | 24 mm-175 mm | 35 | 0 mm-10 mm | 1. Machine applied for ease and consistency 2. Low profile 3. Inexpensive |

| Alligator® Lacing System | 25 mm-356 mm | 4.3-35 | 0 mm-12.7 mm | 1. Hammer applied 2. No installation tool required 3. Low profile |

| Alligator® Spiral Lace System | 10 mm-15 mm | 8.7 | 1.6 mm-6.4 mm | 1. Non-metallic 2. Low profile 3. Non-marking |

| Alligator® Rivet System | 88 mm | 52 | 5 mm -5.8 mm | 1. Strong splice 2. Abrasion resistant 3. Simple installation method and tooling 4. Round hay baling applications |

| Alligator® V-Belt Fastener System | n/a mm | n/a | n/a mm | 1. Fast and easy installation 2. Can be made to any length 3. Strong dependable splice |

Flex-Lag® Rubber Pulley Lagging

To eliminate belt slippage, increase pulley life, improve water shedding, and boost productivity, Flex-Lag® Rubber is a smart, cost-efficient choice. Plus, it can be installed on-site with a fast cold vulcanization process.

Flex-Lag® Diamond-Pattern Lagging – Based on the design of treads used for rain tires, the diamond surface pattern splits the film of water and deflects it into the grooves –– away from the pulleys.

Features and Benefits

- High-durometer rubber for abrasion resistance and water-shedding

- High friction coefficient

Available in SBR and FRAS approved rubber.

Flex-Lag® Plain-Pattern Lagging

It helps prevent belt slippage in the dirtiest environments.

Features and Benefits:

- Horizontal grooves that trap and deflect water from pulleys

- Rubber flexes during use, shedding excess material and preventing build-up

- Much higher friction coefficient than plain sheet-type lagging

Available in SBR and FRAS approved rubber.

Flex-Lag® Light-Duty Lagging

These are ideal for compact pulleys and less demanding applications.

Features and Benefits:

- Raised buttons that channel moisture away from pulleys, while gripping the belt

- Can be used on pulleys with diameters as small as 2″ (50 mm)

Available in black SBR rubber.

Application:

Operations experiencing slippage problems.

Flex-Lag® Medium Ceramic Pulley Lagging

When conventional rubber lagging fails to correct belt slippage, the solution is Flex-Lag® Medium Ceramic Lagging.

Features and Benefits:

- 39% ceramic tile coverage

- Rubber-backed ceramic tiles with a raised “buttons” that embed themselves into the belt’s underside for non-abrasive traction

- Exceptional performance in wet, muddy, or dry conditions

- None of the sharp particles or abrasive edges associated with other ceramic lagging products

Fast, easy installation that doesn’t require removing the pulley from the conveyor

Application:

- Any operation experiencing slippage problems

- For systems with pulley diameters from 12” – 72” (300 – 1800mm)

Specifications:

- Temperature rating: 5° F to 185° F (-15° C to 85° C)

- Rubber compound: SBR

- Rubber hardness: 68 ± 3 Shore A

- Thickness: (15 mm)

- Ceramic compound: Aluminium Oxide (Al₂O₃)

- Ceramic hardness: 83 HRA Rockwell Hardness Scale A

- FRAS (Fire Resistant Anti-Static) MSHA Certification No. IC-190

Flex-Lag® Adhesives

Flex-Lag® Adhesives are a two-part cold bonding system designed specifically for use with rubber-to-rubber and rubber-to-metal adhesion.

Features and Benefits:

- Adhesive and activator mix on a 1:1 ratio for simplified ordering, stocking, and preparation

- Adhesive and Primer utilize a Polychloroprene rubber formula for optimal adhesion and bonding strength

- Free of chlorofluorocarbons (CFCs)

Application:

Rubber to rubber bonding (i.e. cleats, sidewalls)

Rubber to metal bonding (i.e. lagging, chute liner)

Specifications:

- Temperature rating: up to 176°F (80°C) with spikes to 212°F (100°C)

- Primary compound: Polychloroprene rubber

- Primary diluent: Ethyl acetate

- Pot life: 3-5 hours at 72°F (22°C)

- Shelf life: 18 months at 72°F (22°C) – best if used by date on container/bottle

- Colour: Black

Belt Maintenance Tools

Safe conveyor belt maintenance starts with choosing the right tools. Choose from our selection of belt maintenance products including belt clamps, belt cutters, belt lifters, belt squares and belt skivers — all with built-in safeguards to help prevent on-the-job injuries.

Belt Clamps

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| Far-Pul® HD® Belt Clamps | Belt Clamps | 0-1800 |

| SmartClamp™* Belt Clamps | Belt Clamps | n/a |

Belt Cutters

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| Electric Belt Cutter | Belt Cutters | |

| 900 Series* Belt Cutter | Belt Cutters | 0-2130 |

| 840 Series Aluminum Belt Cutter | Belt Cutters | 0-2130 |

| Clipper® 845LD Belt Cutter | Belt Cutters | 0-1800 |

Belt Lifters

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| Flex-Lifter™ Conveyor Belt Lifter | Belt Lifters | 900-2400 |

Belt Maintenance Accessories

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| Accessories | Belt Maintenance Accessories | n/a |

Belt Skivers

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| FSK™ Belt Skiver | Belt Skivers | n/a |

| Flexco® Belt Groover | Belt Skivers | |

| Rough-Top Belt Skiver | Belt Skivers | n/a |

| Alligator® Belt Grinder | Belt Skivers | n/a |

Installation Tools

| NAME | SUB-CATEGORY | BELT WIDTH (METRIC) |

|---|---|---|

| Laser Belt Square | Installation Tools | n/a |

Conveyor Belt Cleaners and Ploughs

Accessories

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| Belt Cleaner Accessories | n/a | n/a | n/a |

Primary Cleaner

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| EZP1 Rockline® Primary Cleaner | Primary Cleaner | 300-1800 | 3.5 |

| EZP1T Primary Cleaner | Primary Cleaner | ||

| EZP1 Stainless Steel Primary Cleaner with White ConShear™ Blade | Primary Cleaner | 300-1800 | 3.5 |

| EZP-LS “Limited Space” Stainless Steel Primary Cleaner with White ConShear™ LS Blade | Primary Cleaner | 300-1500 | 2.5 |

| EZP-LS “Limited Space” Primary Cleaner | Primary Cleaner | 350-1500 | 2.5 |

| MMP Medium Mine-Duty Primary Cleaner | Primary Cleaner | 600-2100 | 5 |

| Stainless Steel MMP Medium-Duty Primary Cleaner | Primary Cleaner | 600-2100 | 5 |

| MHCP Heavy-Duty Cartridge Primary Cleaner | Primary Cleaner | 600-2100 | 6 |

| MHCP Stainless Steel Heavy-Duty Cartridge Primary Cleaner | Primary Cleaner | 600-2100 | 6 |

| H-Type® Primary Cleaner | Primary Cleaner | 450 -3200 | 6 |

Secondary Plough

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| Heavy Duty Floating Blade Belt Plough | Secondary Plough | 900-2500 | |

| Diagonal Plough | Secondary Plough | 900-1800 | |

| V-Plough | Secondary Plough | 450 -2400 | n/a |

Cleaner Blades

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| Replacement Blades | n/a | n/a | n/a |

Secondary Cleaners

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| P-Type® Secondary Cleaner | Secondary Cleaner | 450 -3200 | 6 |

| R-Type® Reversing Secondary Cleaner | Secondary Cleaner | 450 -3200 | 6 |

| MHS Heavy-Duty and Reversing Secondary Cleaner | Secondary Cleaner | 450-2100 | 6 |

| MHS Stainless Steel Heavy-Duty Secondary Belt Cleaner | Secondary Cleaner | 600-2100 | 6 |

| P-Type® Cartridge Secondary Cleaner | Secondary Cleaner | 600-3000 | 5 |

| R-Type® Cartridge Secondary Cleaner | Secondary Cleaner | 600-3000 | 5 |

| MHS Secondary Cleaner with Service Advantage Cartridge™ | Secondary Cleaner | 600-3000 | 6 |

| U-Type® Secondary Cleaner | Secondary Cleaner | 450 -2400 | 6.6 |

| MDWS Dry Wipe Secondary Cleaner | Secondary Cleaner | 600-2100 | 5 |

| Chevron Belt Cleaner | Secondary Cleaner | 450-1500 | 2.5 |

Primary Cleaner

| NAME | POSITION | BELT WIDTH (METRIC) | MAX BELT SPEED (M/SEC) |

|---|---|---|---|

| MHCP-24A | Primary Cleaner | 600 -600 | 6 |

Conveyor Belt Cleats

Designed to improve incline conveying and material containments, our easy-to-install Tatch-A-Cleat® belt cleats, pegs, lugs, and V-guides ensure that your entire load reaches its destination.

Bondable

| NAME | CLEAT/V-GUIDE | ATTACHMENT | FDA APPROVAL |

|---|---|---|---|

| T Cleats | Cleat | Bondable | Yes |

Mechanical

| NAME | CLEAT/V-GUIDE | ATTACHMENT | FDA APPROVAL |

|---|---|---|---|

| Model L | Cleat | Mechanical | Yes |

| Model HD | Cleat | Mechanical | No |

| Econo-Cleat® | Cleat | Mechanical | No |

| Tatch-A-Peg® | Cleat | Mechanical | Yes |

| Tatch-A-Lug® | Cleat | Mechanical | Yes |

| Tatch-A-Guide® | V-Guide | Mechanical | No |

Load-Point Products

When it comes to loading zones, you need effective material containment and belt protection. Our load-point products have been specially designed to control acceleration, deaden impact energy, reduce damaging vibrations, extend belt life, control dust emissions, and other related problems.

Slider Beds

| NAME | ISSUE |

|---|---|

| Flexco Slider Beds | Load Zone Damage |

Impact Beds

| NAME | ISSUE |

|---|---|

| DRX™ Impact Beds | Load Zone Damage |

| Flexco Impact Beds | Load Zone Damage |

Skirt Clamps

| NAME | ISSUE |

|---|---|

| Flex-Lok™ Skirt Clamps | Spillage |

| Flex-Seal™ Skirting System | Spillage |

Belt Trackers

The Flexco line of belt trackers employ the use of friction and tension to correct alignment issues, to avoid forces that can damage your belt. From light to heavy-duty, large or small conveyors, Flexco has a belt tracker that will help you prevent hazardous belt and structural damage.

Belt Positioners

| NAME | BELT WIDTH (METRIC) |

|---|---|

| Belt Positioner™ | 450-2400 |

Belt Trainers

| NAME | BELT WIDTH (METRIC) |

|---|---|

| PT Max™ Belt Trainer | 0-2100 |

| PT Smart™ Belt Trainer | 450-1800 |