Advanced Brands of Electric Motors & Gearboxes in the ACT

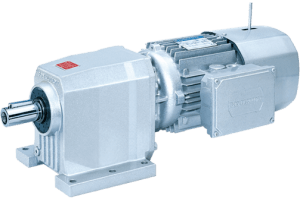

CBS has a range of electric motors, geared motors and gearboxes. We distribute for some of the best known and most advanced brands in the world in, Sumitomo (Japan), Rossi (Spain) and Bonfiglioli (Italy). If there is a brand you require that is not listed, we will source it for you with our well-priced and express service. Due to the large variety of designs and brands of gearboxes please contact us for our professional assistance.

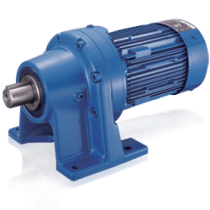

Sumitomo Cyclo® Drive

Cyclo’s unique epicycloidal design has advantages superior to speed reducers that use common involute tooth gears. Cyclo components operate in compression, not in shear.

Unlike gear teeth with limited contact points, a Cyclo has two-thirds of its reduction components in contact at all times. This design enables Cyclo speed reducers and gear motors to withstand shock loads exceeding 500% of their ratings, and provide exceptional performance, reliability and long life in the most severe applications.

Features

- Premier in-line drives as both a reducer and gear motor

- Quiet, efficient and reliable operation with high torque density and compact sizes

- Interchangeable cast iron housings in foot, flanged or face mount configurations

- Available free-shaft, quill hollow shaft, C-face adaptors, shovel base, and top-mount inputs

- Minimal vibration, low noise, low backlash and extended operational life

- The best product warranty with 24 months backs up the superb Cyclo product reputation

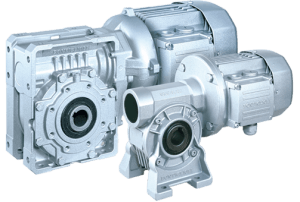

Bonfiglioli VF/W Universal Worm Gearmotor

Bonfiglioli worm gear motor is a milestone for the industry worldwide. They succeeded in combining uncompromising quality with state-of-the-art technology and renowned price effectiveness.

Absolute flexibility is given by the wide choice of several mounting options, shaft configurations and motor interface, all offered as standard. The helical-worm and the double-worm version, with or without the torque limiter, also add up, creating a highly versatile drive system.

Electric Motors

CBS has a range of electric motors from 0.37kw to 630kw in 2, 4, 6 and 8 pole motors. All motors have different ratings for the environment they are being used in from a standard motor or a motor being used in a wash down area where it needs to be waterproof right through to a large motor being used in a mine or quarry where they have to have special sealing arrangements and specialised certifications. We can supply all possible certifications but it is best to talk to us regarding your usage.